[最新] yield strength formula calculation 346902-How to calculate the yield strength

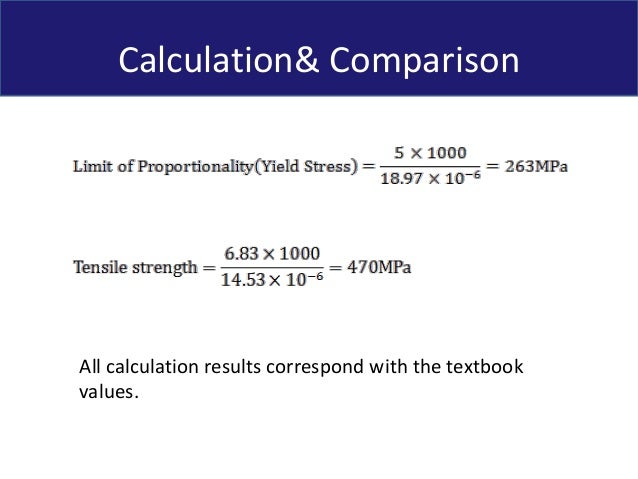

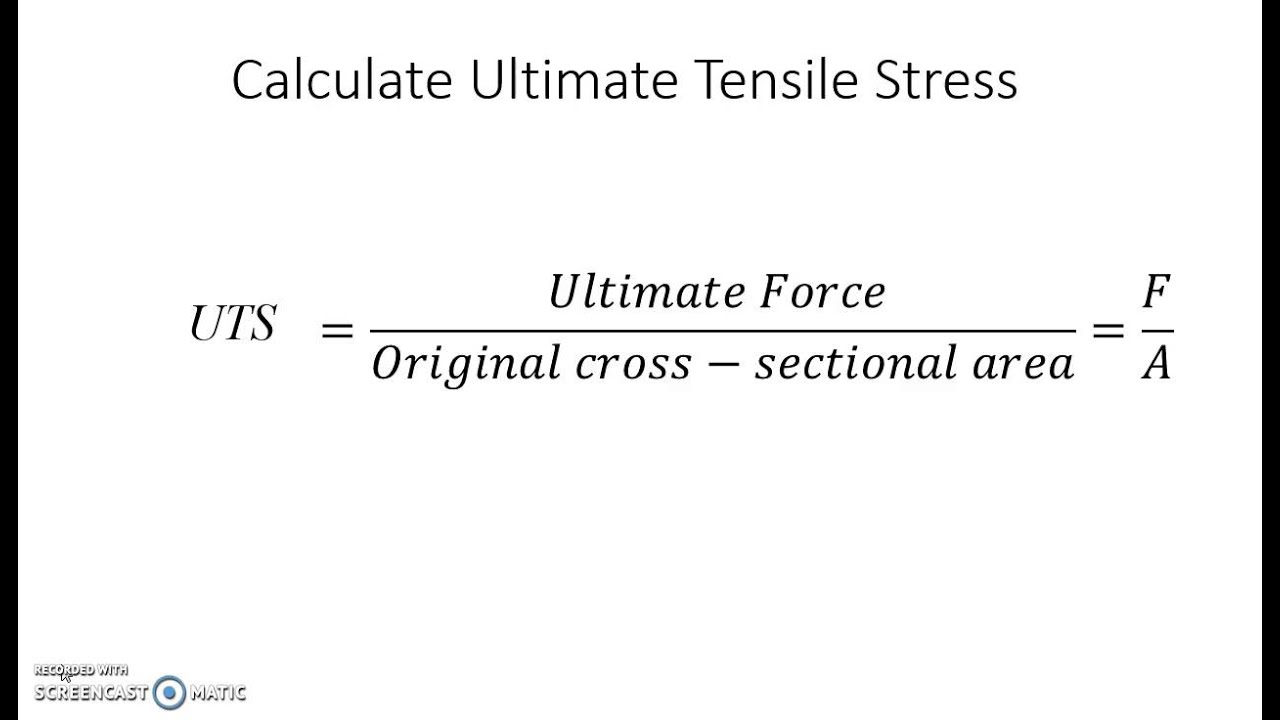

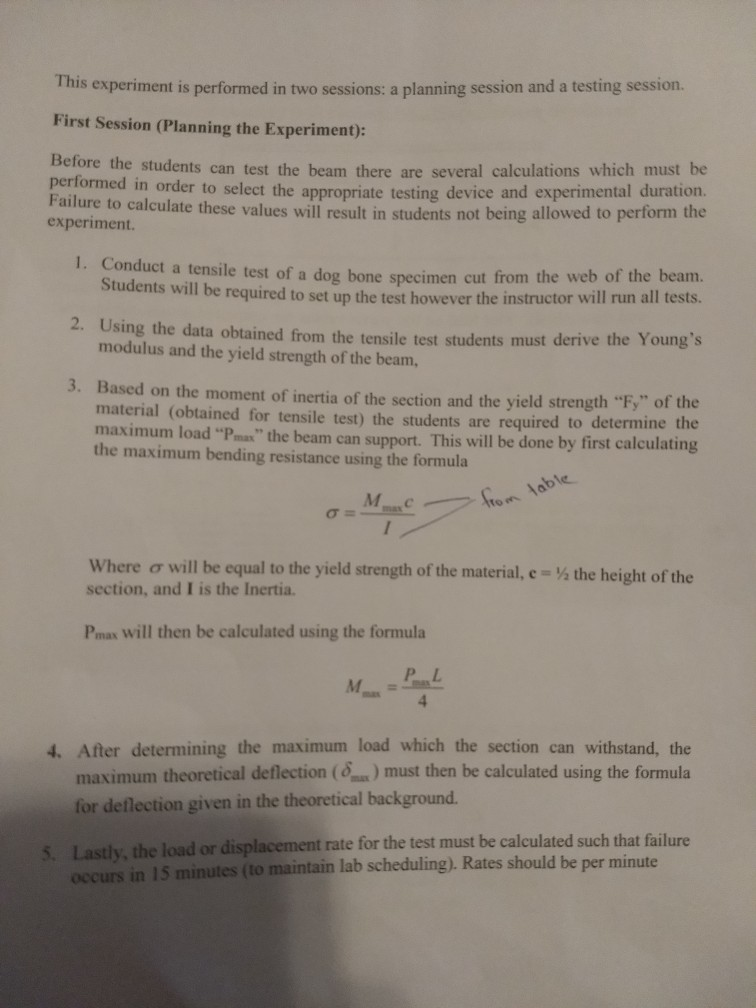

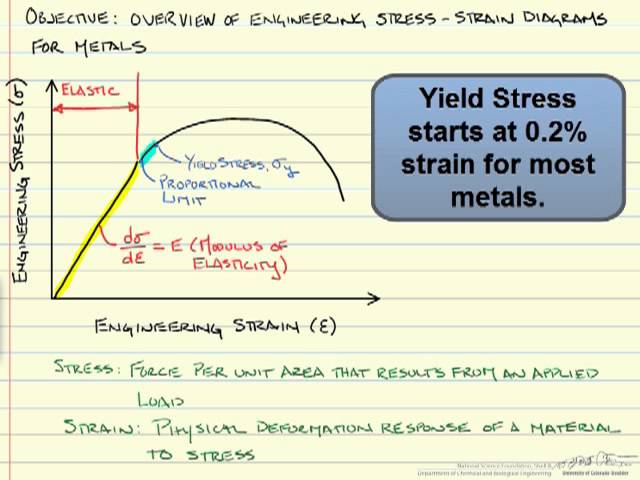

To understand the calculation part you should visit the plant and see the entire process of testing Tensile Strength — The maximum load reached in a tensile test divided by the effective crosssectional area of the gauge length portion of the tesWhen yield strength is reported, the amount of offset used in the determination should be stated For example, "Yield Strength (at 02% offset) = 51,0 psi" Young's Modulus of Common Engineering MaterialsInquiry@TheGriffNetworkcom Mon – Fri 0am – 500pm EST Facebookf Twitter Youtube Linkedin Yield Tables For Film LPDE (Density 092) MICRON MIL G/SQ M G/MSF LBS/MSF SQ INCH/LB 25 1 230 47 36 15 331 68 2122 50 2 460 94 63 25 580 119 75 3 690 Yield Tables for Film Read More »

Determining The Flow Stress Curve With Yield And Ultimate Tensile Strengths Part I

How to calculate the yield strength

How to calculate the yield strength-Additionally, the shear strength of the base metal must also be considered φ Rn = 09 x 06 Fy x area of base metal subjected to shear where, Fy is the yield strength of the base metal For example T Elevation Plan T Elevation Plan Strength of weld in shear Strength of base metal = 075 x 0707 x a x Lw x fw = 09 x 06 x Fy x t x LwThe preload of a bolted joint design is generally based on the tensile yield strength of the bolt or fastener used For the calculations in this post, it will be assumed that the yield strength of the internal threads is larger than the proof strength of the fastener threads, causing the limiting factor to be the fastener used

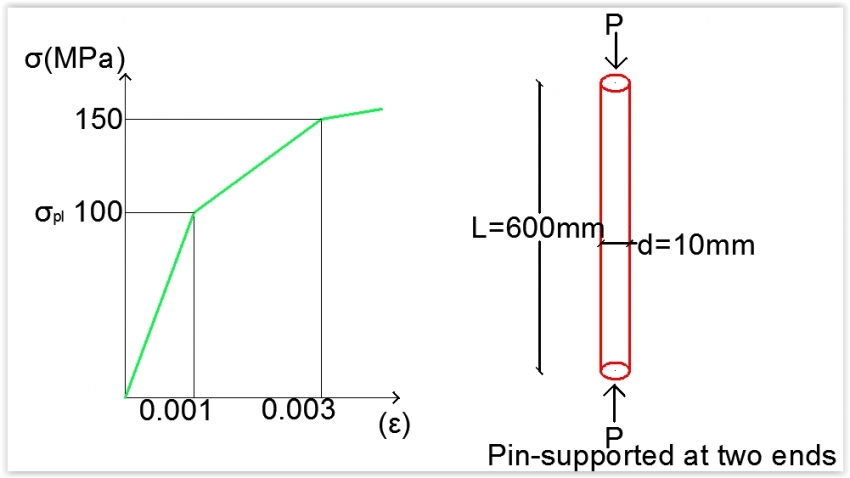

Ch 2 Stress Strains And Yield Criterion

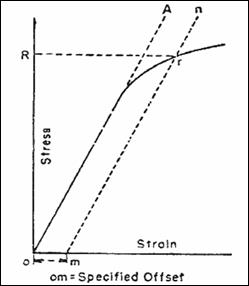

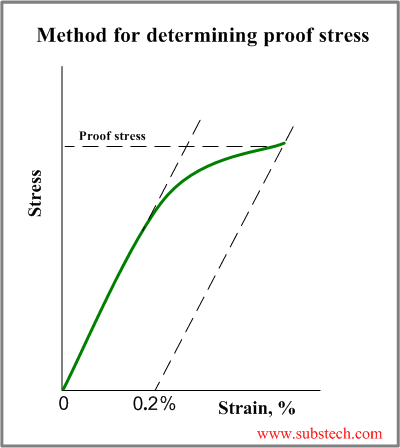

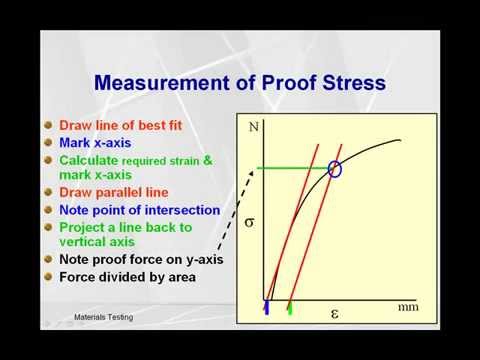

I need to calculate how much force a part can take before breaking Material resin (Flexural Yield Strength 6752 psi) (Tensile Strength 3390 psi) (Density lbs/gal 964) (Durometer Hardness 78) if this isn't enough info, substitute your own material as an exampleDetermine the yield strength by the following methods Offset Method To determine the yield strength by the this method, it is necessary to secure data (autographic or numerical) from which a stressstrain diagram with a distinct modulus characteristic of the material being tested may be drawnUnit Conversion Calculator & Converter for Tensile/Yield & Charpy values Use the following calculator to convert yield or tensile values in ksi, Mpa, N/mm² or psi Type the value in the box next to Mpa (using the drop down to change the unit of measurement)

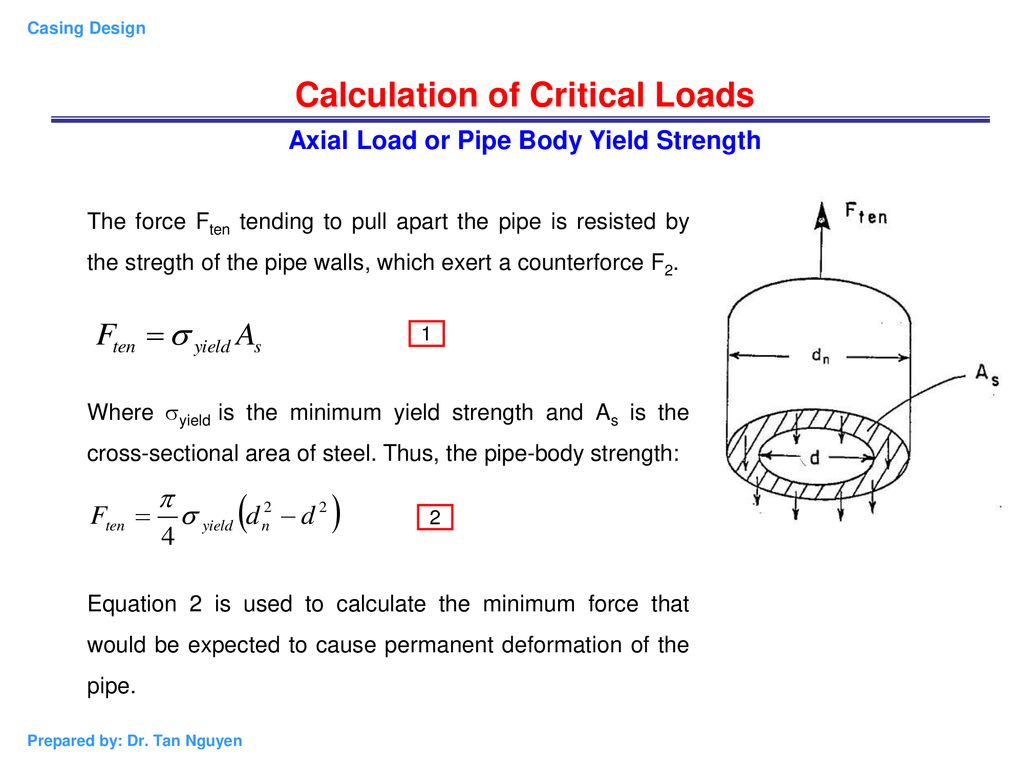

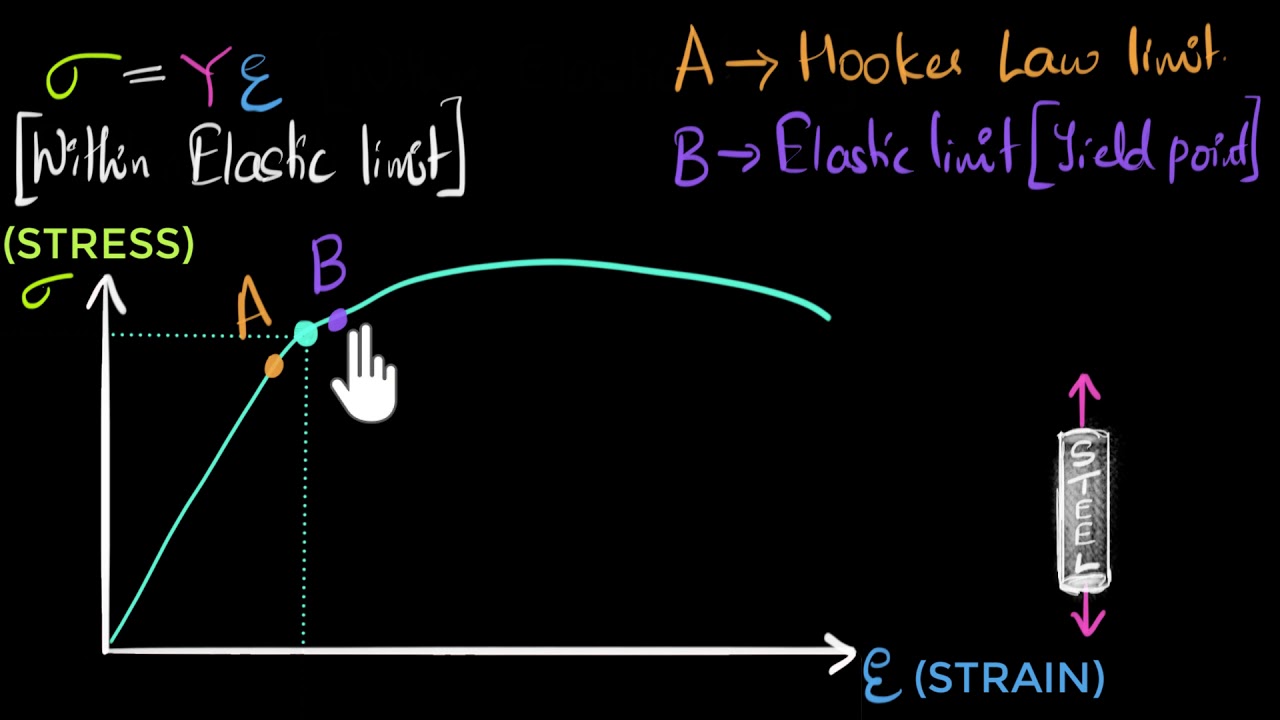

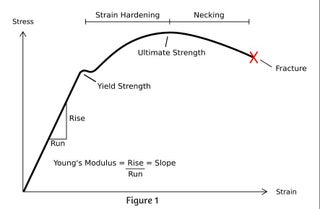

The axial strength of the pipe body is determined by the pipe body yield strength formula found in API Bull 5C3, Formulas and Calculations for Casing, Tubing, Drillpipe, and Line Pipe Properties 1A video of a tensile test of steel is available here https//wwwyoutubecom/watch?v=sQkI_Nj1AxsA video demonstrating how to calculate proof stress is availYield Strength Definition Stress Strain Graph Stress Strain Graph Explanation Yield Strength Graph What is Yield Strength?

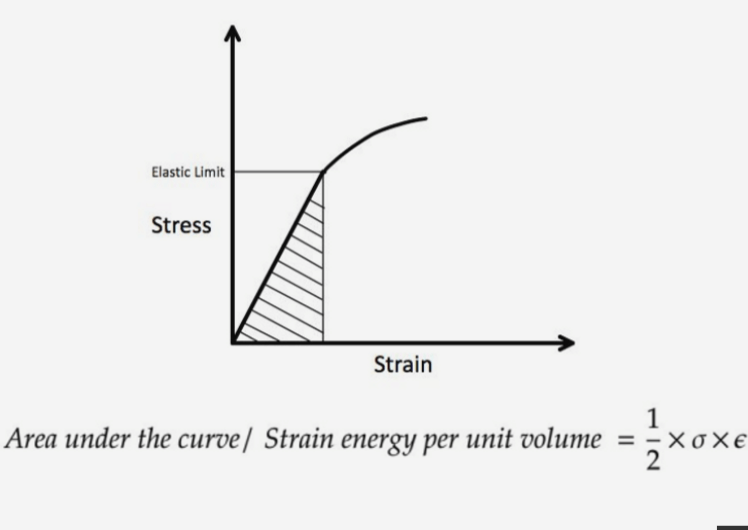

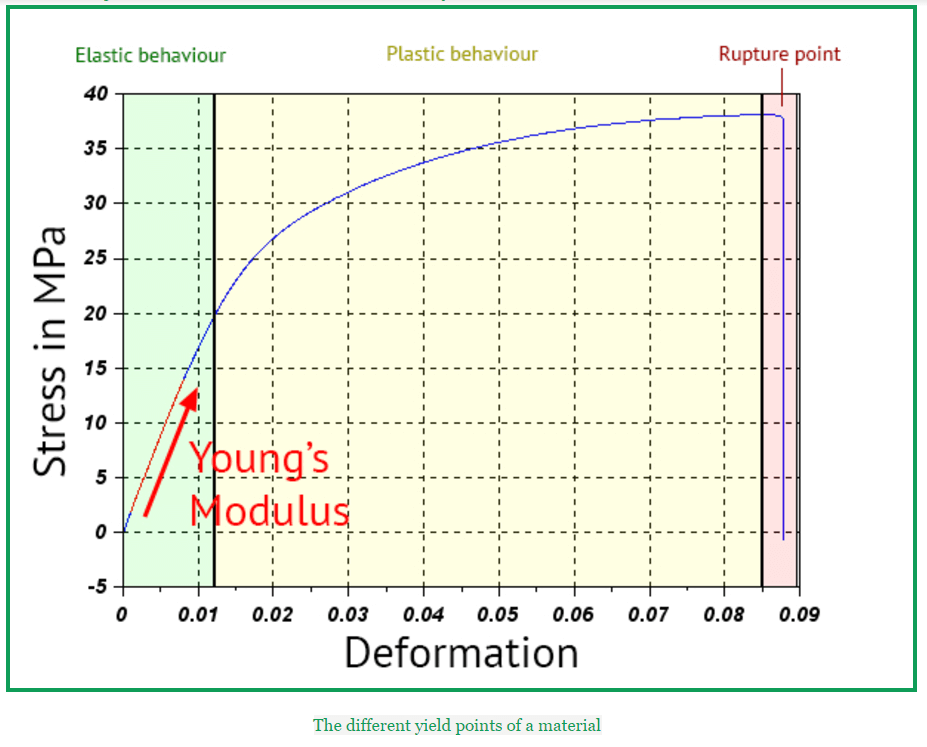

The yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producingYield Strength – Yield Point The yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning plastic behavior Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinearWhether an object is stubborn or malleable is decided by the yield strength It is the point at which an object ceases to be elastic and becomes plastic Yield strength helps us choose appropriate materials for the construction based on the requirement

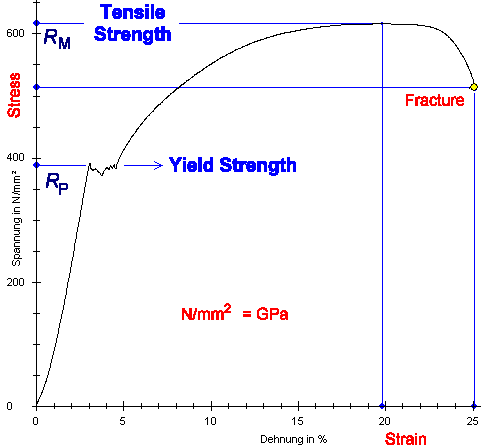

Fracture Point Fracture Strength Stress Strain Curve

To Determine Yield Strength Tensile Strength Of A Steel Bar By Offset Secant Method

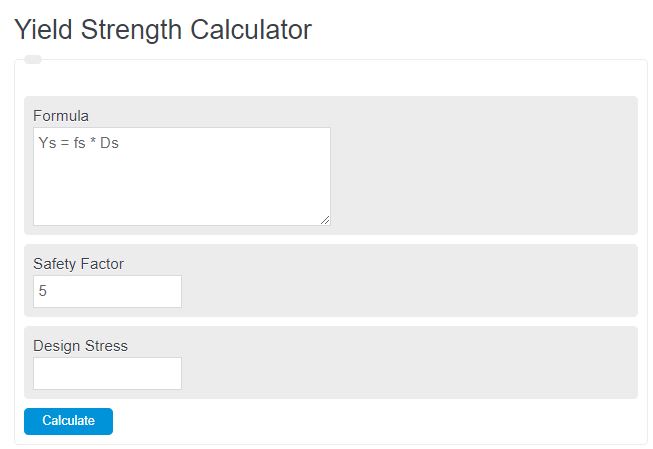

Vickers Hardness Calculator Hardness is a measure of the resistance of a material to plastic deformation induced by applied forces Some materials (eg metals, ceramics) are harder than others (eg plastics, wood) Hardness is an important parameter correlating with wear resistance of the mateFinally, calculate the yield strength Calculate the yield strength using the formula above FAQ What is a yield strength?Yield strength equals approximately one third of the material's hardness, measured in pounds per square inch, but your manufacturer will provide an exact figure If the material yield strength equals 30,000 pounds per square feet and the wall thickness is 3 inches 30,000 x 3 = 90,000 Multiply your answer by 2

Drill Pipe

Phy351 Ch 6

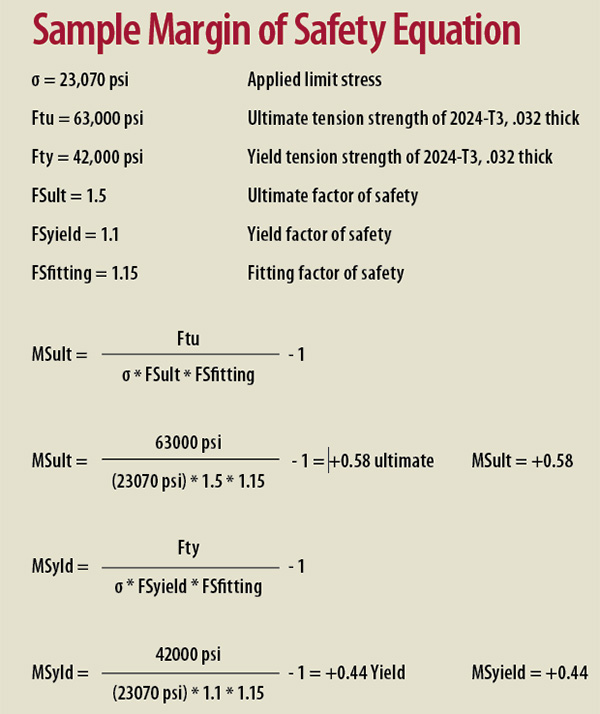

Tensile strength, yield strength, and elongation really do not have such a numerical relationship that can be applied Some people have tried to relate tensile strength to yield strength as a rule of thumb, but these relationships really vary due to processing including heat treatmentI need to calculate how much force a part can take before breaking Material resin (Flexural Yield Strength 6752 psi) (Tensile Strength 3390 psi) (Density lbs/gal 964) (Durometer Hardness 78) if this isn't enough info, substitute your own material as an exampleFirst, determined the safety factor Determine the safety factor of the design Next, determine the design stress

Calculation Methods Of Yield Strength And Ultimate Tensile Strength By Download Scientific Diagram

Tesile Property Of Pipe Drilling Formulas And Drilling Calculations

The yield strength of a material represents the stress beyond which its deformation is plastic Any deformation that occurs as a result of stress higher than the yield strength is permanent Because of the linearity of elastic deformation, yield strength is also defined as the greatest stress achievable without any deviation from theA reaction yield is reported as the percentage of the theoretical amount The formula for percentage yield is given by Percentage yield= (Actual yield/theoretical yield )x100 Rearrange the above formula to obtain theoretical yield formula Example 1 Determine the theoretical yield of the formation of geranyl formate from 375 g of geraniolAdditionally, the shear strength of the base metal must also be considered φ Rn = 09 x 06 Fy x area of base metal subjected to shear where, Fy is the yield strength of the base metal For example T Elevation Plan T Elevation Plan Strength of weld in shear Strength of base metal = 075 x 0707 x a x Lw x fw = 09 x 06 x Fy x t x Lw

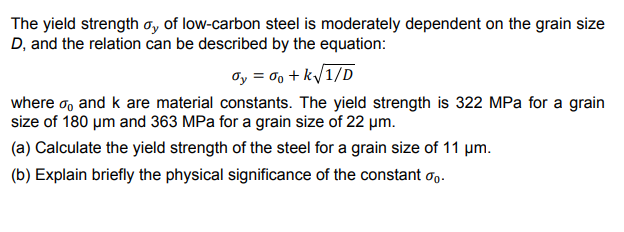

Solved The Yield Strength ơy Of Low Carbon Steel Is Moder Chegg Com

Science Of Uniaxial Deformation

Calculation of Yield Stress For example, aluminum has a yield strength of 14,000 pounds per square inch (or psi), copper has a yield strength of 10,000 psi, and steel, being an alloy ofBarlow's Formula is an equation which shows the relationship of internal pressure, allowable stress, nominal thickness and diameter You can use Trident Steel's calculator tool to determine bursting pressure of line pipeTrident Steel offers ERW line pipe from international and domestic millsUse our calculator below or get a quote on line pipe today(b) The yield strength to be used in determining the internal design pressure under paragraph (a) of this section is the specified minimum yield strengthIf the specified minimum yield strength is not known, the yield strength to be used in the design formula is one of the following (1) (i) The yield strength determined by performing all of the tensile tests of ANSI/API Spec 5L (incorporated

Q Tbn And9gcscfnfqx48qss4 Wjhmulkxh2j5cvtihrqkh8l9ucwk4dpzqblo Usqp Cau

Engineering Stress Strain Curve

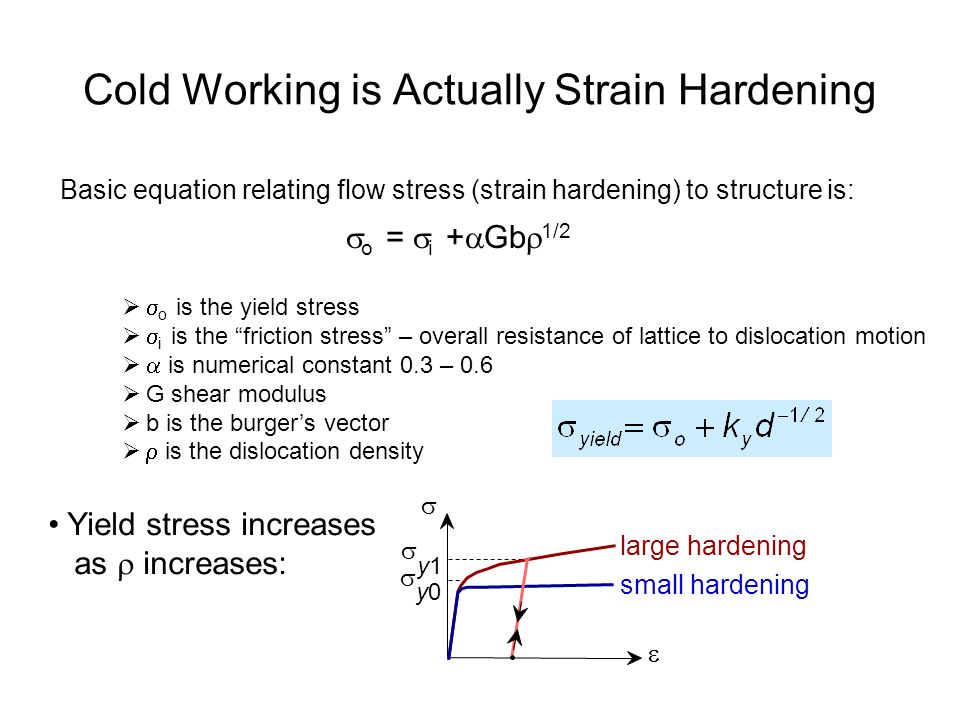

After forming, the yield strength will change due to strain hardeneing So how can I calculate the change in yield strength of the component after it has been formedFactor of Safety When Permissible Value of Maximum Shear Stress is Given calculator uses Factor of safety=05*Tensile Yield Strength/Maximum shear stress to calculate the Factor of safety, The Factor of Safety When Permissible Value of Maximum Shear Stress is Given formula is defined as the ratio of the ultimate strength of a member or piece of material (as in an airplane) to the actualThe point Y is the yield point which corresponds to the yield strength of the material;

Ch 2 Stress Strains And Yield Criterion

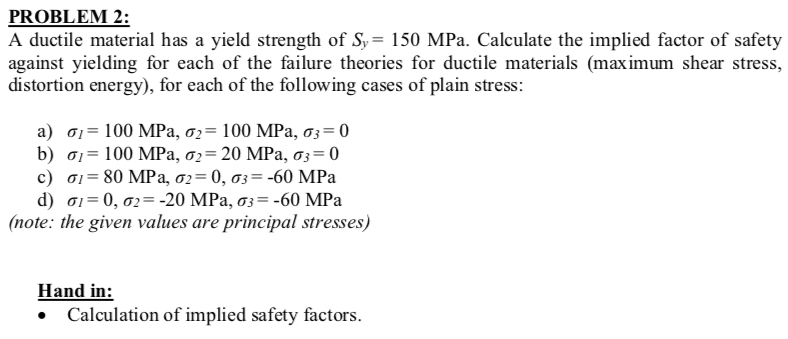

Solved A Ductile Material Has A Yield Strength Of Sy 150 Chegg Com

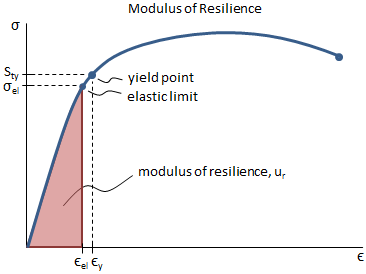

To apply this rule, assume that yield strain is 02 percent, and multiply by Young's Modulus for your material σ = 0 0 0 2 × E \sigma = 0002\times E σ = 0002×E To distinguish this approximation from other calculations, engineers sometimes call this the "offset yield stress"A yield strength is the maximum amount of stress or force that can be applied to a material or object without causing permanent change to the shape In other words, at which point does the material surpass it's elasticThe point U indicates the maximum stress that can be achieved by the material It corresponds to its ultimate or tensile strength The point F is the fracture point Note that the points E and Y may coincide for some types of materials such as ferrous materials

Tensile Test And Stress Strain Diagram Substech

Modulus Of Resilience Definition Calculation 2 Examples

Yield Strength – Yield Point The yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning plastic behavior Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinearUsually, you have to calculate the theoretical yield based on the balanced equation In this equation, the reactant and the product have a 11 mole ratio, so if you know the amount of reactant, you know the theoretical yield is the same value in moles (not grams!)You take the number of grams of reactant you have, convert it to moles, and then use this number of moles to find out how manyThe point Y is the yield point which corresponds to the yield strength of the material;

Ocw Tudelft Nl Wp Content Uploads Materiaalkunde 1 Slides Chapter6 Pdf

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

For accurate calculations, the true stresstrue strain curve for the metal should be drawn to determine the yield strength Figure 16 redrawn on true stresstrue strain axes would look like the one shown in Fig 18Tensile Yield Strength Unit Conversion Calculator;How to calculate a yield strength?

Group Presentation For Tensile Testing

Calculate Yield Stress Youtube

The point at which a material ceases to be elastic and becomes permanently plastic, the point at which it yields, is called its yield point The magnitude of stress at which this transition occurs is known as the material's yield stress or strength The yield strength is a material constant that represents the limit of its elastic behaviorThe yield strength or yield stress is a material property and is the stress corresponding to the yield point at which the material begins to deform plastically The yield strength is often used to determine the maximum allowable load in a mechanical component, since it represents the upper limit to forces that can be applied without producingMathematically expressed von mises stress formula is used to find the yield strength of any ductile material You can refer the below von mises stress equation to find σ vJust, multiply normal stresses (σ x) and (σ y)Then square the shear stress (t xy) and multiply it with 3Now add the two derived values along with the square of normal stress (σ y)

What Is The Relationship Between Ultimate Tensile Strength Young Modulus And Elongation At Break

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Ductile Iron Pipe Equations Formulas Design Calculator Solving for yield strength note Under most cases, S y = 400 pound/inch 2 for ductile iron Inputs internal pressure (P) outside pipe diameter (D o) net pipe wall thickness (t) Conversions internal pressure (P) = 0 = 0 pound/inch^2 outside pipe diameter (D o) = 0 = 0 inch netThe point U indicates the maximum stress that can be achieved by the material It corresponds to its ultimate or tensile strength The point F is the fracture point Note that the points E and Y may coincide for some types of materials such as ferrous materialsHow to calculate yield strength The stressstrain diagram for a steel rod is shown and can be described by the equation ε=0 (1e06)σ0 (1e12)σ 3 where s in kPa Determine the yield strength assuming a 05% offset

Yield Strength Strength Mechanics Of Materials Engineers Edge

Minimum Yield Strength An Overview Sciencedirect Topics

Barlow's Formula is a calculation used to show the relationship between internal pressure, allowable stress (also known as hoop stress), nominal thickness, and diameter It is helpful in determining the maximum pressure capacity a pipe can safely withstandUsers must determine the yield strength for casing and screen This measures the point at which the casing or screen will be damaged by deformation due to the stress of the hanging weight This calculation is used to evaluate suitability of use relative to expected loadsThe ultimate strength design method is similar to LRFD There is a nominal strength that is reduced by a factor which must exceed the factored design stress For beams, the concrete only works in compression over a rectangular "stress" block above the na from elastic calculation, and the steel is exposed and reaches the yield stress, F y

Calculate Proof Stress Youtube

How To Find Yield Strength Quora

The ultimate strength design method is similar to LRFD There is a nominal strength that is reduced by a factor which must exceed the factored design stress For beams, the concrete only works in compression over a rectangular "stress" block above the na from elastic calculation, and the steel is exposed and reaches the yield stress, F yMaterial 1045 Steel, Yield Strength= 530 MPa, Ultimate Strength= 625MPa Max Stress o The shaft is keyed for a 1/8" key, thus the actual yield strength can be equated to ¾ the materials yield strength (Keyed Yield Strength=398 MPa) o Loading is comprised of three components MomentBased on the axle length between bearings and radial loadSheet thickness (in) Die edge radius (in) Punch edge radius (in) Bend length (in) Ultimate tensile strength (psi) Factor of safety

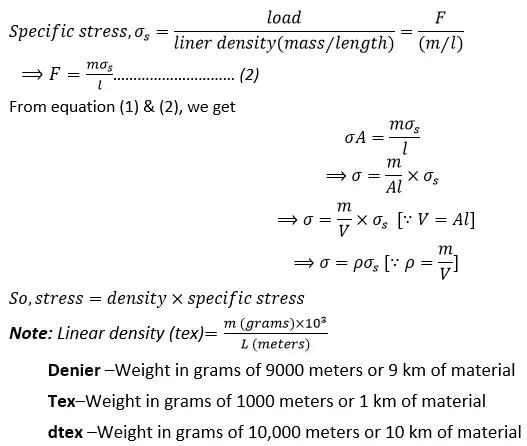

Tensile Testing Terms And Tensile Testing Terms Definitions Textile Study Center

What S The Difference Between The Elastic Modulus And Kinetic Modulus Machine Design

Ductile Iron Pipe Equations Formulas Design Calculator Solving for yield strength note Under most cases, S y = 400 pound/inch 2 for ductile iron Inputs internal pressure (P) outside pipe diameter (D o) net pipe wall thickness (t) Conversions internal pressure (P) = 0 = 0 pound/inch^2 outside pipe diameter (D o) = 0 = 0 inch net6 Specified Minimum Yield Strength >3,500 psi 7 Maximum Allowable Operational Pressure (MAOP) 125 psi According 16 NYCRR §, the design pressure formula for plastic pipe is the following p = 25 x 032 SDR 1 Where P= Design Pressure, psig S= Hydrostatic Design Basis (HDB) at pipeline operating pressure, psigA video of a tensile test of steel is available here https//wwwyoutubecom/watch?v=sQkI_Nj1AxsA video demonstrating how to calculate proof stress is avail

Cold Working Is Actually Strain Hardening Basic Equation Relating Flow Stress Strain Hardening To Structure Is O I Gb 1 2 Yield Stress Increases Ppt Download

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Burst Pressure What It Is And Why It S So Important Corrosion Materials

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

Compression Springs How To Calculate Spring Stress Tokai Spring Industries Inc

What Are Tensile Strength Units Quora

Solved Using Tensile Test Graph Stress Vs Strain And Pr Chegg Com

A Comparative Evaluation Of Metallurgical Properties Of Stainless Steel And Tma Archwires With Timolium And Titanium Niobium Archwires An In Vitro Study Vijayalakshmi R D Nagachandran K S Kummi P Jayakumar

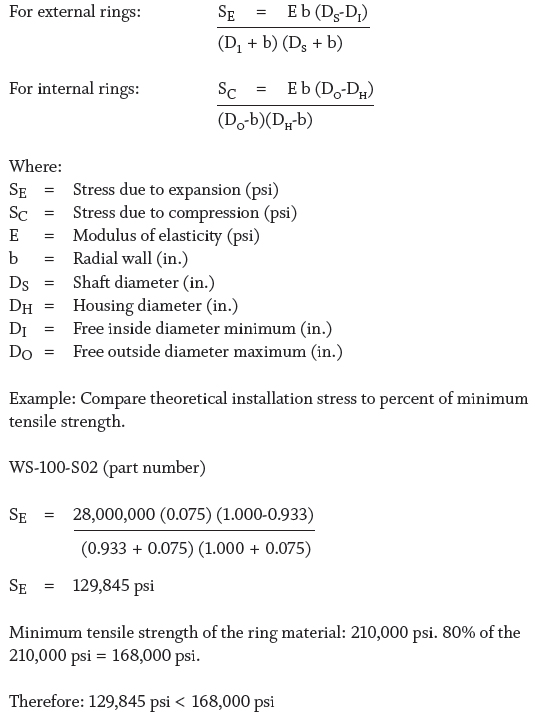

Careful Calculations Affect Ring Design

How To Measure Tensile Strength Elastic Modulus And Ductility Rolled Alloys Inc

Http Www Csun Edu Bavarian Courses Mse 527 Tension Test Mse 527l Pdf

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Http Www Schooloftesting Com Download How To Interpret Stress Strain Diagrams How to interpret stress Strain diagrams Pdf

Mechanical Properties Of Materials Mechanicalc

What Is 0 2 Of Offset Method In Yield Strength Quora

Yield Strength Definition Examples Stress Strain Graph Faqs

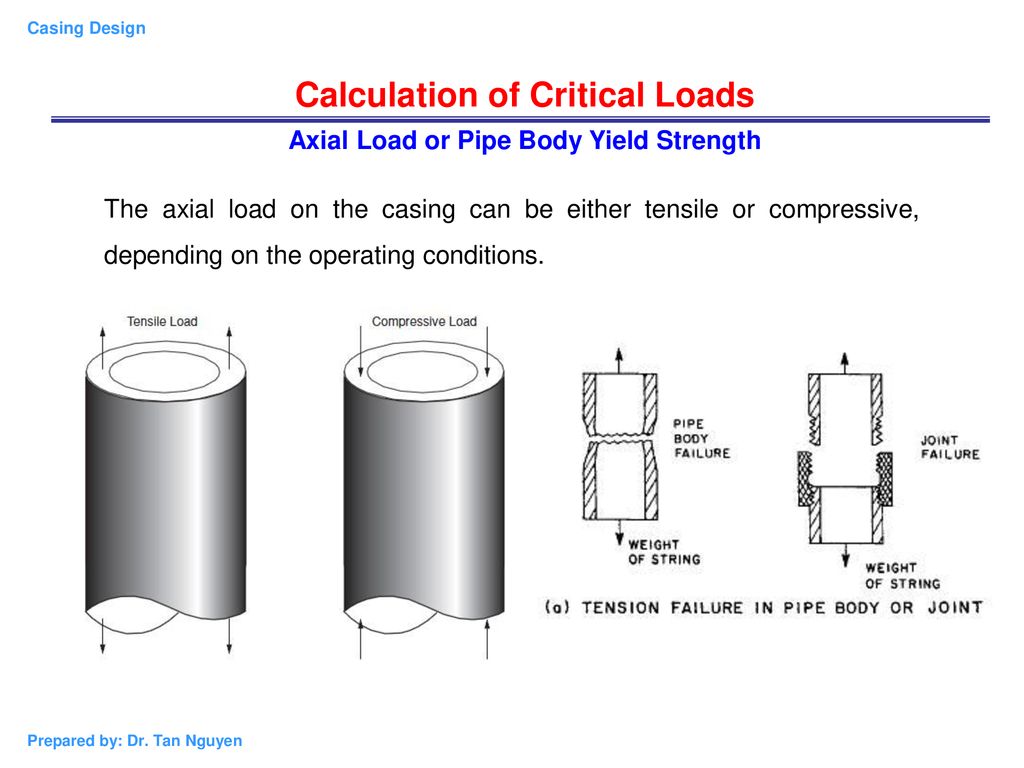

Chapter 2 Casing Design Calculations Of Loads On A Casing Ppt Download

How To Find Yield Strength Quora

Link Springer Com Content Pdf 10 1007 Bf Pdf

Strength Of Materials Basics And Equations Mechanics Of Materials Engineers Edge

Chapter 2 Casing Design Calculations Of Loads On A Casing Ppt Download

Stress Strain Curve Wikipedia

Stressing Structure

Modulus Of Elasticity Instron

Stress Vs Strain Curve Video Khan Academy

Cee 3710 Strength Versus Stiffness

What Is Yield Stress Definition Formula Video Lesson Transcript Study Com

Yield And Tensile Strength Engineering Materials Youtube

What Is Proof Load Of A Bolt And How Is It Different From Yield Strength Smartbolts

Machinning And Materials The Blog From A Lean Thinker

Strength And Stiffness Characteristics

Finding 0 2 Offset Strain Dplot

Basic Of Drillpipe Tensile Capacity And Its Calculation Drilling Formulas And Drilling Calculations

Importance Of Yield Strength Plastic Deformation To Civil Engineers

Http Web Ncyu Edu Tw Lanjc Lesson C3 Class Chap02 A Pdf

Mechanical Properties Of Materials Mechanicalc

Yield Strength Calculator Formula Calculator Academy

Q Tbn And9gcsumns2x3 Webzskkkrhb14nvbc6w7vc87d 1jgykyqyya0frej Usqp Cau

Determining The Flow Stress Curve With Yield And Ultimate Tensile Strengths Part I

The Differences Between Stiffness And Strength In Metal

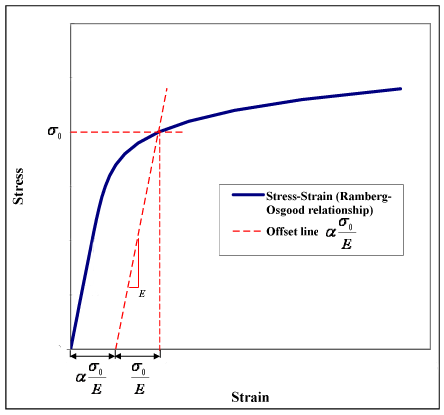

Ramberg Osgood Relationship Wikipedia

Yield Engineering Wikipedia

Strength At Break Tensile

Strength At Break Tensile

Young S Modulus And Tensile Strength All You Need To Know

Calculation Example Critical Load Thestructuralengineer Info

Pressure Rating Of Steel Cylinder Tubing Womack Machine Supply Company

Engarc L Offset Yield Method

Strength Of Materials Basics And Equations

Calculation Of Properties For Casing Strings

What Is The Formula For Tensile Strength How Is This Determined Quora

Www Usna Edu Naoe Files Documents Courses En380 Course Notes Ch10 Deformation Pdf

Shear Yield Strength An Overview Sciencedirect Topics

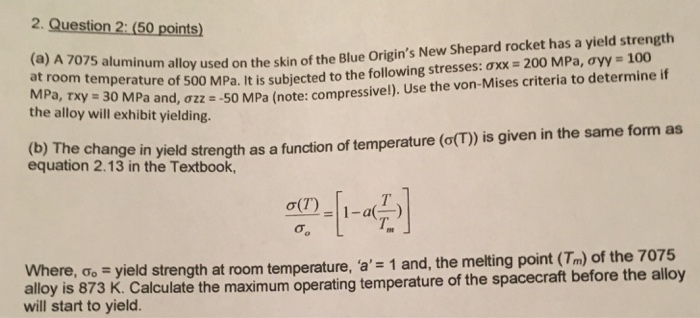

Solved 2 Question 2 50 Points A A 7075 Aluminu At Ro Chegg Com

Thread Yield And Tensile Strength Equation And Calculator Engineers Edge Www Engineersedge Com

Link Springer Com Content Pdf 10 1007 Bf Pdf

Ch 2 Stress Strains And Yield Criterion

Strength At Break Tensile

Calculation Methods Of Yield Strength And Ultimate Tensile Strength By Download Scientific Diagram

Api 6a 21st Ed Gate Valves Design Allowables Valve Engineering Eng Tips

Home Iitm Ac In Kramesh Strength of materials laboratory manual Pdf

Failure Strength Sf From Re Rm R 0 2 E And Efailure

Tesile Property Of Pipe Drilling Formulas And Drilling Calculations

Steps To Analyzing A Material S Properties From Its Stress Strain Curve 9 Steps Instructables

Tensile Test Experiment Materials Science And Engineering Michigan Technological University

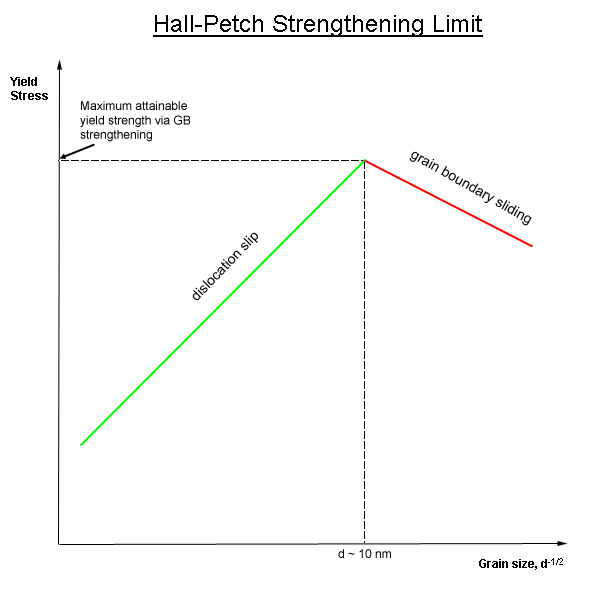

Grain Boundary Strengthening Wikipedia

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

Machinning And Materials The Blog From A Lean Thinker

Stress Strain Diagrams Youtube

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

Finding 0 2 Offset Strain Dplot

Api 6a 21st Ed Gate Valves Design Allowables Valve Engineering Eng Tips

Yield Strength Strength Mechanics Of Materials Engineers Edge

How To Find Yield Strain Corresponding To 0 2 Offset Yield Stress

Http Documents Dps Ny Gov Public Common Viewdoc Aspx Docrefid Fb3a5391 F447 4276 Af 9f8a0d6da3

Q Tbn And9gct6phcuvy2nvnyhsgbnilcko Dvidytrlpedy3hopugz2nclqo3 Usqp Cau

How To Design For Stiffness Using Material Properties Fictiv

コメント

コメントを投稿